VANNES RIGAU located in Lomme - France, supplies the French & European power Industries since 1937. In 2005, SUD ROBINETTERIE INDUSTRIE (SRI), the French ball valves manufacturer founded in 1978 in Marseille, France, bought VANNES RIGAU to broaden their products line of high quality isolation valves to include gate, globe and check valves.

VANNES RIGAU is a qualified supplier for worldwide and national companies including end-users and EPC contractors in oil, gas and steam applications.

VANNES RIGAU uses the latest technologies like CAO, DAO and structural calculations in the conception, verification, analysis and testing of its products.

VANNES RIGAU is qualified ISO 9001 and PED 2014/68/EU module H.

Parallel Slide Gate Valve

Bolted bonnet

Bolted bonnet

Gate valves are used primarily as on/off valves to release or block a fluid flow,

in high temperature applications such as medium pressure saturated steam or low temperature application.

Gate valves advantages are, low pressure drop, bi-directional, effortless closing system, resistant to thermal stress,

good lifetime thanks to slide parallel discs and good sealing whatever pressure service.

A spring is fitted between the discs to provide initial sealing force.

The disc is also pushed against the seat by the differential pressure thus reducing the operating force at low pressures.

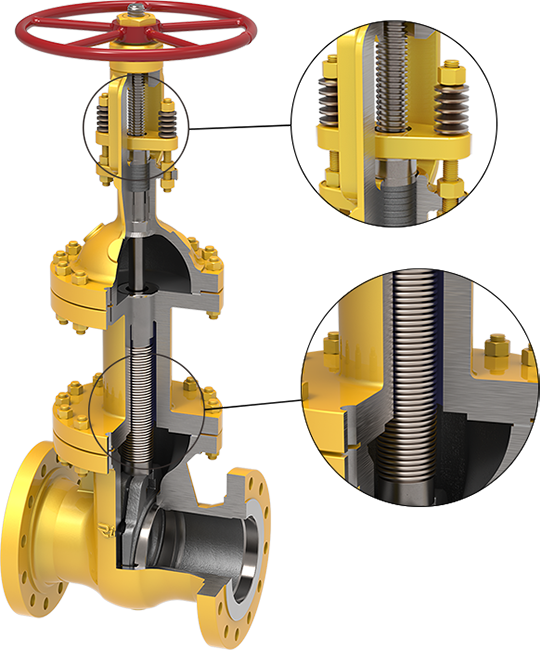

Pressure seal bonnet

Pressure seal bonnet

Gate valves with pressure seal are used primarily as on/off valves to release or block a fluid flow in high temperature

and high pressure superheated steam applications.

The main advantage of pressure seal is that pressure inside the valve body compresses the gasket to assure sealing.

In case of high pressure buildup such as water hammer, the bolted bonnet seal contact pressure may drop causing leakage.

In the case of pressure seals, the bonnet seal contact pressure remains constant.

Bolted

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

API 600 design and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Hub ends - Grayloc type

Manual or actuated operation

Chain wheel operation

Bonnet extension upon request

Locking device

Heating jacket

Transition pup pieces or nipples

By-pass

Cavity pressure equalization by manual or actuated valve

Removable seats on dynamic seal pockets

Welded ends

Pressure seal bonnet

Range

ND 3/4" (DN20) to ND 16" (DN400)

Classes

ASME CLASS 600 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Design features

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Hub ends - Grayloc type

Manual or actuated operation

Chain wheel operation

Locking device

Transition pup pieces or nipples

By-pass

Cavity pressure equalization by manual or actuated valve

Removable seats

Flexible Wedge Gate Valve

Bolted bonnet

Bolted bonnet

Wedge gate valves are the most common valves.

They are primary used as on/off valves to release or block a fluid flow, at low, ambient or high temperature, and in various pressure classes.

Wedge Gate valves advantages are low pressure drop, bi-directional.

Wedge gate valve can be flexible, spli, or solid.

Pressure seal bonnet

Pressure seal bonnet

Wedge gate valves are the most common valves. They are primary used as on/off valves to release or block a fluid flow, at low,

ambient or high temperature, and in various pressure classes.

The main advantage of pressure seal is that pressure inside the valve body compresses the gasket to assure sealing.

In case of high pressure buildup such as water hammer, the bolted bonnet seal contact pressure may drop causing leakage.

In the case of pressure seals, the bonnet seal contact pressure remains constant.

Bolted bonnet

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

API 600 design and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Hub ends - Grayloc type

Manual or actuated operation

Chain wheel operation

Bonnet extension upon request

Locking device

Transition pup pieces or nipples

By-pass

Cavity pressure equalization by manual or actuated valve

Removable seats on dynamic seal pockets

Bellow seal on stem

Pressure seal bonnet

Range

ND 3/4" (DN20) to ND 16" (DN400)

Classes

ASME CLASS 600 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Titanium

Design features

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Hub ends - Grayloc type

Manual or actuated operation

Chain wheel operation

Locking device

Transition pup pieces or nipples

By-pass

Cavity pressure equalization by manual or actuated valve

Removable seats

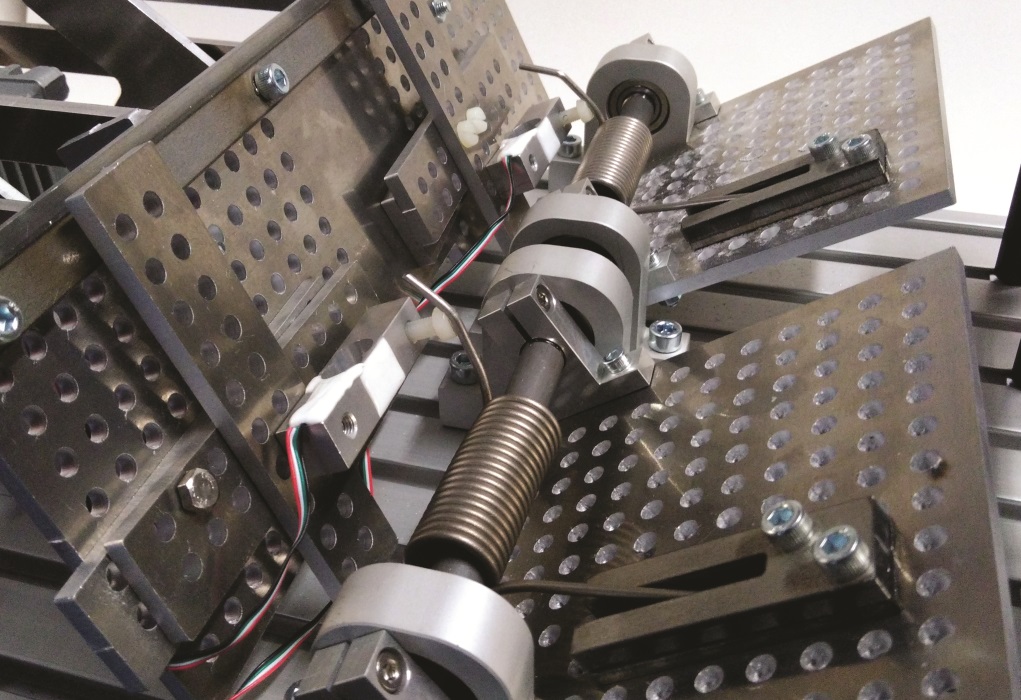

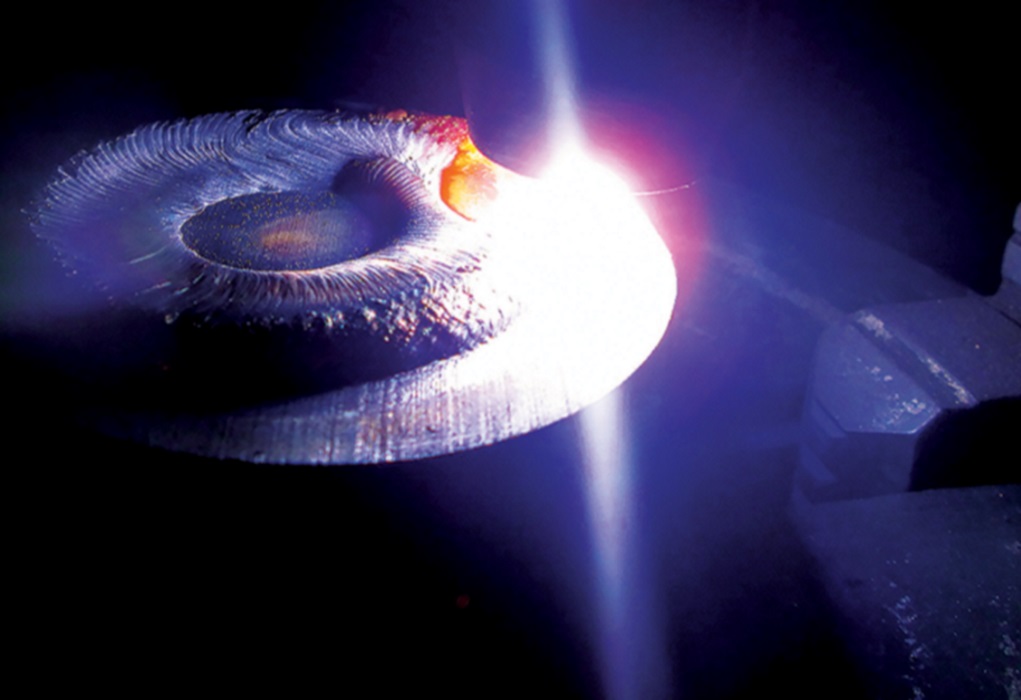

Engineering & Technologies

Vannes RIGAU uses the latest techniques like CAD, DAO and structural calculations in the conception,

verification, analysis and testing of their products.

A permanent research and development program leading to patents means always more reliability and performance in our products.

Vannes RIGAU is equipped with a finite element analysis software ANSYS.

This software can simulate: Thermal, solid mechanics, mechanics of fluid, fluid/structure interaction.

Globe Valve

Bolted bonnet

Bolted bonnet

Globe valves are used for throttling flow, and to release or block a fluid.

The flow pattern through a globe valve involves changes in direction, resulting in flow resistance and causing a high pressure drop.

To limit this pressure drop, Vannes RIGAU can also propose "Y" pattern glove valve.

Vannes RIGAU globe valves can be equipped with an actuator and its positioner. In order to be used as a control valve.

Pressure seal bonnet

Pressure seal bonnet

Globe valves are used for throttling flow and to release or block a fluid.

The flow pattern through a globe valve involves changes in direction, resulting in resistance flow and causing high pressure drop.

To limit pressure drop, Vannes RIGAU can also propose "Y" pattern globe valve.

Pressure seals are generally used for high pressure service. This design prevents a water hammer effect that can be a cause of bolted bonnet seal leakage.

Vannes RIGAU globe valves can be equipped with an actuator and its positioner in order to be used as a control valve.

Pressure seal bonnet

Range

ND 2" (DN50) to ND 16" (DN400)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Design features

BS 1873 design and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Connection ends upon request

Manual or actuated operation

Chain wheel operation

Bonnet extension upon request

Locking device

Transition pup pieces or nipples

Removable seats

Hub ends - Grayloc type

Inclined body type

Bellow seal on stem

Pressure seal bonnet

Range

ND 2" (DN50) to ND 16" (DN400)

Classes

ASME CLASS 600 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Design features

BS 1873 design and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Connection ends upon request

Manual or actuated operation

Chain wheel operation

Bonnet extension upon request

Locking device

Transition pup pieces or nipples

Removable seats

Hub ends - Grayloc type

Inclined body type

Swing Check Valve

Bolted bonnet

Bolted bonnet

Swing check valves are used to protect installations against blackflow.

They are entirely operated by reaction of flow and then do not require any external actuation.

Bolted bonnet is common for low pressure valves, but Rigau can propose bolted bonnet for high pressure service.

Swing check valves can also be manufactured with a piggable design.

They can be fitted with an actuator in order to block the disc in closed position.

Or they can be fitted with a dash pot to reduce tilting.

Pressure seal bonnet

Pressure seal bonnet

Swing check valves are to protect installations against backflow. They are entirely operated by flow direction and they do not require an external actuator.

Pressure seals are generally used for high pressure service. This design prevents the water hammer effect that can be a cause of bolted bonnet seal leakage.

Swing check valves can also be manufactured with a piggable design.

They can be fitted an actuator in order to block the disc in closed position.

Or they can be fitted with a dash pot to reduce tilting.

Bolted

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

BS 1868 desgin and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Manual or actuated operation

Manual or actuated locked position or fail position

Transition pup pieces or nipples

Removable seats

Piggable

Piston version

Hub ends - Grayloc type

Pressure seal bonnet

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 600 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

BS 1868 desgin and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Manual or actuated operation

Manual or actuated locked position or fail position

Transition pup pieces or nipples

Removable seats

Hub ends - Grayloc type

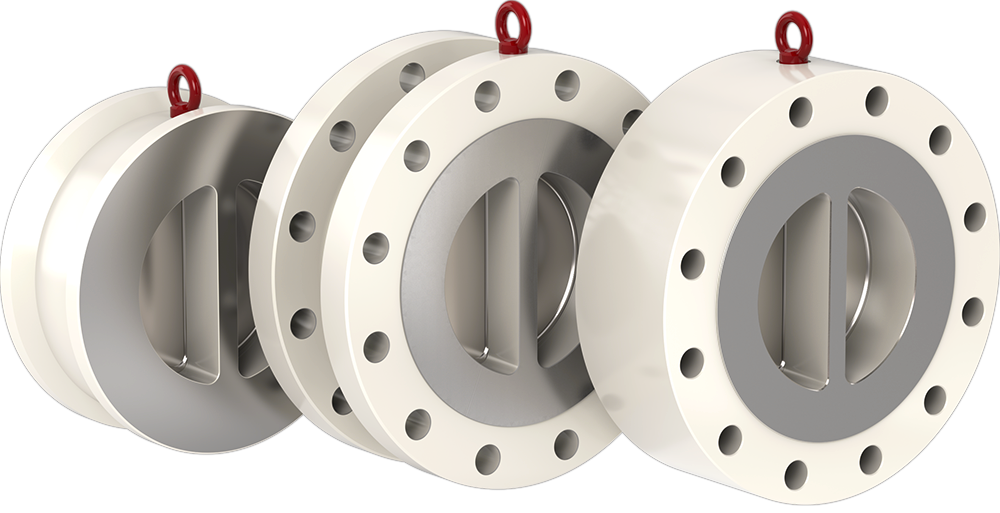

Dual Check Valve

Wafer/Flanged/Lug

Wafer/Flanged/Lug

Dual plate check valves are used to protect installations against backflow.

They are entirely operated by reaction of flow and they do not require any external actuation.

The main advantages of dual plate check valves vs swing check valves are: lightweight, short dimensions.

Moreover, line shock is reduced or eliminated. Due to the reduced face to face this check valve can be mounted vertically or

horizontally thanks to a return spring.

Dual check valve can be designed as wafer, lug or flanged type.

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 300 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

API 594

ASME B16.34 design and construction

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Spring customary setting

Quality & Certification

Vannes Rigau complies with the ISO requirements for its complete cycle of management,

conception, production and trading.

This quality system is qualified ISO 9001 and also allows Rigau to be qualified PED 2014/68/EU module H.

Starting up instructions following PRBE026F

Please click on logo to show.

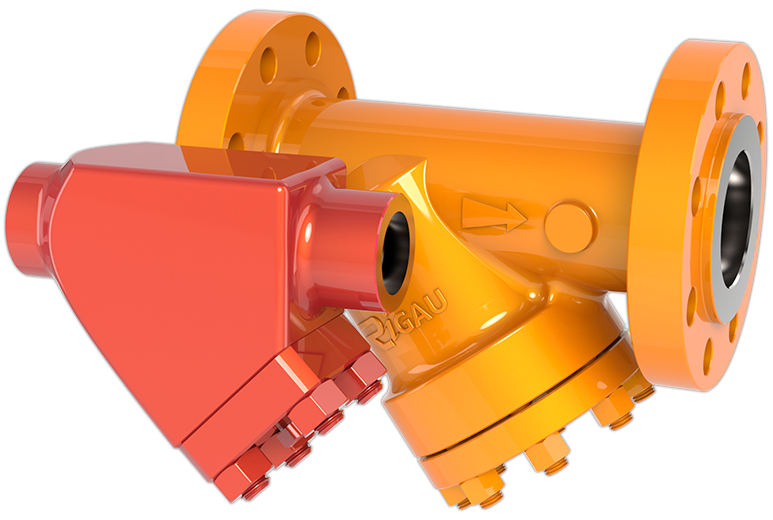

Strainer

Y-Type

Y-Type

Strainers should be installed upstream to protect an installation from scales and dirt.

The larger items fall to the bottom and are held in a basket for later disposal.

On demand, strainers can be made from cast or forged material.

Vannes RIGAU strainers can be customized in order to match your process requirement

(pressure drop calculation, filtration size, differential pressure monitoring).

Range

ND 1/2" (DN15) to ND 10" (DN250)

Classes

ASME CLASS 150 to 1500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

ASME B16.34 design and construction

Inclined body type (Y-type)

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Hub ends - Grayloc type

Transition pup pieces or nipples

Straigth body type (T-type)

Magnetic inserts

Handle for heavier cover

Pressure drop control device

Other Vannes Rigau products

Cryogenic

Cryogenic

Rigau can adapt its gate and globe valves for cryogenic application.

Vannes Rigau selects adequate material (austenitic stainless steel etc.) for low temperature service (minimum temperature: -196°C).

The bonnet is extended in order to guaranty ambient temperature for the packing.

Through conduit

Through conduit

Slab gate valves have two floating seats permit in-line sealing.

The wedge of expending gate valves is considered by two parts; when the operator finishes closing the expending gate valve,

the two parts of the wedge push on seats and assure in-line sealing.

Cryogenic

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

BS 1868 desgin and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Manual or actuated operation

Manual or actuated locked position or fail position

Transition pup pieces or nipples

Removable seats

Piggable

Piston version

Hub ends - Grayloc type

Through conduit

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

API 600 design and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

connection ends upon request

Hub ends - Grayloc type

Manual or actuated operation

Chain wheel operation

Bonnet extension upon request

Locking device

Heating jacket

Transition pup pieces or nipples

By-pass

Cavity pressure equalization by manual or actuated valve

Removable seats on dynamic seal pockets

Welded ends

Other Vannes Rigau products

Quick opening valve

Quick opening valve

The use of rack & pinion system allows a quick opening of the valve.

It can be fitted with a spring return device.

Quick opening valves can be used for cleaning the installation by steam flushing.

Counterweight check valve

Counterweight check valve

To adjust opening pressure of the swing check valve, Rigau can install counterweight.

Or they can be fitted with a dash pot to reduce tilting.

Counterweight check valve

Range

ND 2" (DN50) to ND 24" (DN600)

Classes

ASME CLASS 600 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex

Nickel Alloys

Design features

BS 1868 desgin and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Straigth body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Manual or actuated operation

Manual or actuated locked position or fail position

Transition pup pieces or nipples

Removable seats

Hub ends - Grayloc type

Manufacturing

Vannes RIGAU has a workshop equipped with a full complement of CNC and machining equipment,

in order to have best quality and fast delivery for each product.

Vannes RIGAU machining capabilities is always evolving in order to increase our abilities.

All the raw materials used for the machining come from European industry.

Our goal is to manufacture the best quality possible in all our products.

Optional Design Features

By-pass

By-pass

On demand, Vannes RIGAU can install by-pass valve (gate, globe, ball, needle or multiport valve). By-pass valve can have several functions :

- Maintain a residual flow when the main valve is close (for example to start a factory)

- Reduce the difference of pressure between upstream and downstream to operate the main valve and reduce opening torque

- Avoid overpressure on valve cavity By-pass valves are adapted to fluid pressure, fluid temperature and fluid corrosivity

Y-type globe valve

Y-type globe valve

Globe valves can be delivered with Y-type bodies in order to reduce pressure drop across the valve.

By-Pass

Vannes RIGAU can install by-pass valve on gate, globe, ball, needle or multiport valve. The technical specifications depends on the by-pass valve.

Y-Type

Range

ND 2" (DN50) to ND 16" (DN400)

Classes

ASME CLASS 150 to 2500

Material

Carbon & low alloy Steels

Stainless steels

Duplex & Super Duplex

Nickel Alloys

Design features

BS 1873 design and construction

ASME B16.34 design and construction

Face to face as per ASME B16-10

Welded seat

Inclined body type

On request

Full/reduced/customize bore

Manual or actuated operation

Optional Design features

Connection ends upon request

Manual or actuated operation

Chain wheel operation

Bonnet extension upon request

Locking device

Transition pup pieces or nipples

Removable seats

Hub ends - Grayloc type

Straigth body type

Live loading

Live loading is an addition of spring washers to the gland studs to maintain the packing load of the valve over time.

Bellow seal

The bellow seal replace the dynamic sealing system of a stem packing by a static sealing system between the valve bonnet and the valve stem bottom. It prevents the valve from the risk of leakage from the valve packing for VOC or toxic services.

All our valves can be equipped with an actuator or a gearbox.